Tuesday, June 10, 2008

Risk Analysis May Lead to Changes

Wednesday, May 28, 2008

Root Cause Analysis, Part 2

Photos from http://www.csititanic.com/.

Photos from http://www.csititanic.com/.Research indicates that the rivets used were poorer quality than standard, causing an easy fracture path for failure. The research was conducted on many rivet samples retrieved from the shipwreck site. Photomicrographs show the phosphate and sulphate inclusion level in these iron rivets is excessive, leading to a weaker fastening of the ship. You can see this on the scanning electron micrograph, shown below from www.csititanic.com, which shows a long slag inclusion provided a fracture path for this rivet's failure.

This was a policy decision made by managers at Harland and Wolff. The basic motivator is the drive for profits which, in this case, trumped the need for quality. So to avoid the sinking of the Titanic, an executive at Harland and Wolff would have had to say, “no, we cannot meet this schedule and build the three ships safely with materials that are currently available, so we must delay one or two of the ships.” This would have allowed proper materials to be used and would have saved 1520 lives.

This analysis shows that most problems are the cause of policy decisions and ineffective management, not workers like watchmen or riveters. It was an officer who didn’t supply the binoculars, it was an executive who specified the wrong rivets rather than changing the schedule.

The root cause of the Titanic's sinking so quickly was an executive decision far removed from the sinking, both in space and time; As Deming said, “The problem is at the top, management is the problem.”

Friday, May 23, 2008

Lean @ Home

We use lean manufacturing principles at work, and they provide huge benefits. Why don't we have a "Lean @ Home" program? What would that look like?

According to the National Bestseller, The Machine that Changed the World, lean principles include

- Teamwork

- Communication

- Efficient use of resources and elimination of waste

- Continuous improvement

Teamwork

A team can take a huge leap forward in performance by simply clearly committing to work toward the common goal. Understanding others’ points of view is sometimes required before moving forward. Sometimes roles must be clarified. At home, teamwork is very important. Working together with the family toward common goals is an important concept. The goals can include financial, educational, spiritual, social, physical fitness, organizing the home, and many others. By agreeing and setting goals, groups living at home move toward success.

Communication

Many problems find their root cause in poor communication. In today's world of high technology, there is no excuse for poor communication. At home, we can use e-mail, voice mail, notes on the fridge, and best but maybe least used: talking face to face. Communication is key to achieving a lean home.

Efficient use of resources and elimination of waste

The objective of a lean system is to identify and eliminate waste. There are seven areas of waste identified in the Toyota Production System:

- overproduction,

- waiting,

- transporting,

- inappropriate processing,

- excessive inventory,

- motion,

- defects.

Translating this into the home, the wastes become

- bad habits occupying time,

- non-useful idle time,

- commute time,

- inefficient methods, including wasted energy

- hoarding,

- extra steps,

- errors.

Continuous Improvement

A key hallmark of continuous improvement is having a system in place to root out problems, discovering and solving them before they impose themselves on you. These systems function well in good companies, and they can save your home life from excessive waste.

Tools used in creating lean enterprises can be adjusted to develop lean homes. The effort is underway at our house and I will update this blog with lessons on the journey.

Wednesday, May 21, 2008

Root Cause Analysis

o Standard operating procedures at that time for ice fields: post watchman and carry on.

· Why 2: Why did the watchman see the iceberg too late? Conditions:

o “Flat calm,” cloudless sky, 31 F. Watchmen looked for the white foam of waves crashing on icebergs' bases. That night, there were no waves.

o Moonless night: difficult to see anything.

o Not ideal conditions to see icebergs, but was the Titanic not to travel in these flat seas?

o Yes, it should be able to steam in these conditions. Since we can’t control the conditions, let’s step back up and ask why the watchmen failed to see the berg until it was too late. Did the watchman have standard tools, like binoculars?

· Why 2/B No. Why didn’t the watchman have binoculars to see in poor conditions?

o He was told they didn’t have them by an officer, even though there were two pair in the bridge.

· Why 3: Why denied?

o The officer didn't know or didn't care enough to find out. In essence, this is poor communication.

· Why 4: Why poor communication?

o If we answer this, we know why the Titanic hit the iceberg: root cause was poor communication between the watchman and the officer.

- Why 5: why didn't the officer know about binoculars on the bridge?

- Poor training, new ship, lack of leadership and awareness... these are the problems, as Deming said, "at the top."

So we see, it wasn't that the watchman did a poor job, it was that he was not supported by the management system. This failure led to the Titanic striking an iceberg on its maiden voyage. Next we'll ask why the ship, described as "practically unsinkable," sank so quickly once it hit.

Monday, May 12, 2008

Profitable Ideas

People wonder if ideas can make money -- yes, there are profits in ideas. Take personal investing, for example. Investing in the right security yields profits. Essentially, we have the equation

People wonder if ideas can make money -- yes, there are profits in ideas. Take personal investing, for example. Investing in the right security yields profits. Essentially, we have the equationGood Idea + Investment = Profit.

There are millions of "good ideas" on how to invest money, and often people hire experts to provide them with investment ideas (stock broker, financial planner, etc.). One problem with this arrangement is that often the expert "hired" really works for a firm who sells investments. Clients wonder, "Who holds sway over this expert, me the client -- or the firm, his employer?" Conflicts of interest occur. For those like me who are self-reliant and don't mind simple online research, I developed a system that generates good investment ideas using free online tools. The method solves the conflict, removing it from clients' worries.

First, I advocate the value investment philosophy proven effective by such icons as Warren Buffett and Benjamin Graham. I recommend reading Graham's book, The Intelligent Investor.

Grounded in the knowledge of how value investing works, you can begin searching for profitable ideas. In Graham's day, people pored over printed materials. One beautiful thing about investing today is that there are so many new tools to get results. I use an advanced, free stock screening tool. I use screening parameters I developed based on the value philosophy and generate lists of potential investments. I take those results to information boards, such as Yahoo's finance page for more detailed analysis of companies I like. Once I gain the knowledge of the business and confirm that it is worth the investment, I place the trade myself. I monitor the results and have a target sales price on the up and down side.

This method generates profits from ideas, true idea power. The key is establishing optimal parameters and maximizing your profit. I will share my stock screening parameters soon, a quick "how to" for today's value investor, but am also interested in other views, so comments are encouraged!

Check back soon for links to my course on value investing, how to pick winning investments, which is under revision temporarily.

Friday, May 9, 2008

Effective Meeting Course

- decide if a meeting is necessary and elminate bad ones

- plan effectively for a meeting

- execute an effective meeting

- write an effective report

- effectively run a virtual meeting

In this four-part class you will learn how to shine as a star in meeting effectiveness.

I use Digital Chalk to present my course. Click here to create a new account and register for the course. Complete four sessions, pass the exam with at least 70%, and receive a certificate of completion. Upon completion, you will also receive a .pdf checklist to use for future reference as you plan for effective meetings.

Use your new skills immediately to improve your results, get noticed: a great investment at $59.00. Guarantee: if you pass the class, implement the methods, and are not satisfied with your results, you will receive a full refund.

Friday, April 25, 2008

How to get better ideas... and more of them!

- Have a learning plan. Think about what you need to know and focus your efforts on the highest value information that is easiest to learn.

- Regular aerobic exercise is vital... even walking works, and practice good breathing.

- Limit caffeine but keep a pretty steady stream of it in small amounts throughout the day

- Figure out and use your learning style, whether it be visual, kinesthetic, listening, or tactile.

1: Distract Yourself -- this is possibly a good approach for memorizing but seems hard to do.

2: Caffeinate With Care -- good advice; one cup of coffee a day followed by small, regular doses

3: Choose Impressive Information -- interesting idea... memorize useful and easy facts

4: Think Positive -- great advice for learners: a virtuous cycle!

5: Do the Right Drugs -- huh?

6: Juice Your IQ Score -- good advice that ties with 3 and 4

7: Know Your Brain -- exactly how does this help?

8: Don't Panic -- right on... how do we not panic? If you do, know your IQ plummets.

9: Embrace Chaos -- mix up things to make them somehow easier to remember.. counter intuitive.

10: Get Visual -- for visual learners, a big YES

11: Exercise Wisely -- breathing and aerobics... the brain uses a disproportionate amount (20%) of the oxygen in your blood, so improving your cardio-vascular system will help your brain.

12: Slow Down -- good advice for improving reading comprehension, but practice at reading quickly does work, so aim for the optimal: 500 wpm according to the article.

Thursday, April 17, 2008

Titanic Mistake

This photo of the Titanic under construction comes from the NY Times article describing a recent discovery concerning the sinking of the great ship. The Titanic was designed to be unsinkable, yet it sunk on its maiden voyage. The discovery shows why the Titanic sunk from striking an iceberg, and why it sunk so quickly, taking so many with her.

This photo of the Titanic under construction comes from the NY Times article describing a recent discovery concerning the sinking of the great ship. The Titanic was designed to be unsinkable, yet it sunk on its maiden voyage. The discovery shows why the Titanic sunk from striking an iceberg, and why it sunk so quickly, taking so many with her.In the article, reported by William J. Broad, research by Jennifer Hooper McCarty and others shows the cause of the disastrous sinking was faulty rivets located in the bow. A transition from iron rivets to steel rivets was underway in shipbuilding of the times, and steel was the newly preferred, stronger material. Steel rivets were used in the areas designers felt it was most needed, in the main hull, but not in the bow nor stern. Iron rivets were specified, and there were shortages. A lower grade iron rivet was used in the Titanic, as demonstrated in samples recovered from the ship. When compared to standard wrought iron, there is up to three times the inclusions, or trapped slag, in the iron. Inclusions make the steel weaker, providing fracture paths for failure propagation.

How could this be? This was a premium luxury liner of the time and there were cheap rivets? It is a story of a crisis with seeds in decisions far removed from the chilly arctic where the Titanic lays today. In an earlier post, I described a model for a crisis with an adverse outcome:

- An initial problem, often minor in isolation, that goes uncorrected

-A subsequent problem that compounds the effect of the initial problem

- An inept corrective effect

- Disbelief at the accelerating seriousness of the situation

- Generally, an attempt to hide the truth about what is going on while an attempt is made at remediation

- Sudden recognition that the situation is out of control or “in extremis”

- Finally, the ultimate disaster scenario involving significant loss of life, financial resources, or both, and ultimately, the recriminations.

* Initial problem: material shortages. There were three huge ships being built at the same time and materials and labor were in short supply. Iron rivets were substituted for steel and used in the bow.

* Subsequent problem compounding the initial one: the proper iron rivets were not ordered (due to a shortage?) and the ones received had inclusions, weakening them. They came from smaller forge shops not normally used by the shipbuilder.

* Corrective Effect: There was none that we know because the iron rivets were not tested and found to be weaker than required. The Board of Trade stopped inspecting iron rivets at the time, deciding they were a mature technology and the focus went to steel.

* Disbelief at the accelerating seriousness: this had to occur the night the Titanic hit an iceberg. Due to the weaker rivets, the Titanic literally fell apart at the seams in the bow, allowing water to rush in and sinking the ship faster than anyone could respond.

* The final disaster scenario: the sinking of the Titanic with all the loss of life and property associated with it.

Interestingly, denial and recriminations persist to this day. When asked about the research findings, the shipbuilder, "Harland and Wolff, after its long silence, now rejects the charge. 'There was nothing wrong with the materials,' Joris Minne, a company spokesman, said last week. Mr. Minne noted that one of the sister ships, the Olympic, sailed without incident for 24 years, until retirement. (The Britannic sank in 1916 after hitting a mine.)"

The Titanic rests at the bottom of the Atlantic, with six slits in its bow. The slits replace seams once held closed by iron rivets, and the slits stop where the steel rivets hold the seams together still.

Wednesday, April 9, 2008

Total Productive Maintenance

There are three phases to implementing TPM: the first phase is training people and gathering data, the second phase is to cure breakdowns and micro-stops (equipment stops less than 5 minutes), and the third phase is prevention of future breakdowns. Phase 1 involves collecting data on the current status of equipment uptime or OEE. It also involves training maintenance professionals and equipment operators in TPM philosophy and actions required. The best training results in a change in mindsets among the team. The team comes to realize the importance of the goal of increasing OEE and knows their part in doing so.

Next, the team works to implement curative actions. Here, equipment is brought up to par with new equipment, or better. All major systems are reviewed and upgraded, new or rebuilt components are installed to cure breakdowns. Data is collected on micro stops, and systems are put in place to minimize these small disruptions. This is where TPM makes the most impact, by measuring and addressing micro stops, capacity is uncovered and the manufacturing system performs closer to ideal.

Once downtime is reduced and equipment is running stably, a prevention phase begins. Here 5S activities (workplace organization) are key to maintaining the improvements set in phase 2 of TPM. Maintenance schedules should be established and reviewed periodically to ensure preventive measures are effectively supporting the new OEE. Here, too, effective teams review and revise their maintenance activities to ensure continued improvement.

Implementing the three phases of TPM sounds like a lot of work... or it should. TPM is an investment; it takes time, money, and expertise to implement. It pays dividends in improved quality, better delivery, lower inventory, and reduced need for capital. For the lean enterprise, TPM is a necessity.

Thursday, April 3, 2008

Happy E-Day!

Today is E-Day, short for Engineer's-Day, a day of celebration at my Alma mater, the Colorado School of Mines. The fireworks shown are from the 1984 version of E-day, when I was a senior. E-Day goes back to 1927 when Mines held it's first E-Day. The celebration is steeped in tradition and pride, as shown from this quote from the Mines site, referring to the 2000 E-Day brochure: "One thing that has remained the same through E-Days of past, present, and the future, is the weekend starts with the most spectacular fireworks show in the state and ends with seniors graduating a month later to become the best engineers the world has to offer." There were only 65 graduates that year of the first E-Day, and they studied mineral engineering: Metal Mining, Metallurgy, Geology, and Petroleum Engineering.

Mines grew a lot over the years, and now is the leading engineering school for a wide variety of mineral engineering and related disciplines. I have always respected the intellectual rigor of Mines and its students. The depth and breadth of curriculum is impressive by any standard. There has always been a very conservative, traditional air about the school. Now I hear about a new program that was recently announced, a Minor in Humanitarian Engineering. This is surely a new Mines... one that is taking on new challenges this generation feels passionately about. Here, engineering students take design and humanities courses to prepare them to implement improvements or alleviate vulnerabilities in under served communities in the developing world. What a great way to get the best and brightest out there making a true difference.

I proudly graduated in 1984, and to commemorate, I pulled this photo off the Mines website: http://www.mines.edu/. This year, to celebrate E-Day, we're hosting a get-together for any other alumni and their guests here in Western North Carolina. Click here for details. I hope to see many Miners!

Wednesday, April 2, 2008

Reflections of a Leader... Updated

“It is clear from the events and ideas I have described that my generation had an opportunity unique in the history of American industry. When we started in business, the automobile was a new product, and the large-scale corporation was a new type of business organization. We knew that the product had a great potential, but I can hardly say that any of us, at the beginning, realized the extent to which the automobile would transform the United States and the world, reshape the entire economy, call new industries into being, and alter the pace and style of everyday life.” -- Alfred Sloan, Jr.

Fast forward to 2008... Let’s do a find & replace on this passage, replacing automobiles with computers, and let’s replace new with monolithic. Perhaps Mr. Jobs or Gates will write this some day:

It is clear from the events and ideas I have described that my generation had an opportunity unique in the history of American industry. When we started in business, the computer was a monolithic product, and the large-scale corporation was a monolithic type of business organization. We knew that the product had a great potential, but I can hardly say that any of us, at the beginning, realized the extent to which the computer would transform the United States and the world, reshape the entire economy, call new industries into being, and alter the pace and style of everyday life.

Today, computers and information play a central role in the economy, in business, in the production of goods and services, including automobiles. While GM led the way to building great wealth through large organizations with huge economies of scale, the computer ushers in an age of building wealth through information exchange. Economies of scale come from mass customization, not mass production. Successful, lean manufacturers know this and know how to use information to their advantage.

Monday, March 31, 2008

Technolgies for Group Cooperation

- easy to use

- open

- self-instructing

- enable connection

- group forming

- leverage self-interests that adds up to more

He shows us a glimpse of the future with powerful handheld devices linking us in powerful groups and discusses the new wealth which will accompany this revolution. Check it out!

Friday, March 28, 2008

Trends: Instapreneur

Wired Magazine has a great article this month on business trends and a fascinating look at instapreneurs. This is a trend to watch, and participate in. The process seems simple: a designer uploads their design to a website such as ponoko, zazzle, or styleshake, and let buyers order the product. An outsourced firm manufactures the product with short lead time (like two weeks) and profits go to the designer.

Wired Magazine has a great article this month on business trends and a fascinating look at instapreneurs. This is a trend to watch, and participate in. The process seems simple: a designer uploads their design to a website such as ponoko, zazzle, or styleshake, and let buyers order the product. An outsourced firm manufactures the product with short lead time (like two weeks) and profits go to the designer. Thursday, March 27, 2008

Simply Powerful Meetings: A Quick Overview

View from the Grove Park Inn, Asheville, courtesy of Grove Park Inn.

View from the Grove Park Inn, Asheville, courtesy of Grove Park Inn.Simply Powerful Meetings are just that. We plan and execute meetings that matter. Subjects vary depending on your needs but can include

- strategic planning SWOT analysis,

- critical success factor development,

- focused improvement,

- action planning,

- initiatives development,

- matrix analysis

When you need to get a group together, we promise you will achieve far better results with us.

I have a new course on effective meetings... click here and create a new account to check it out!

Wednesday, March 26, 2008

Cost Reduction

Knowledge

o Discretionary Policy

§ Wages

§ Technology

§ Mix

§ Service level

§ Material specifications

§ HR policies

o Learning

§ Plant layout

§ Schedule improvement

§ Labor efficiency

§ Design changes

§ Increased yield

§ Increased utilization

§ Tailoring raw materials

· Relationships

o Linkages

§ Internal

· Optimize

· Coordinate

· Inventory

§ External

· Channels

o Interrelationships

§ Share savings

o Integration

§ Reduce cost

§ Increase market power

· Macro Issues

o Location

o Institutional factors

o Timing (first to market, mover?)

· Volume

o Scale

o Utilization patterns

Art Imitating Life... Science

Tuesday, March 25, 2008

Asheville Retreats

A view of Asheville, NC in March, 2008. Photo by Bob Michel

A view of Asheville, NC in March, 2008. Photo by Bob Michel"You seldom get what you go after unless you know in advance what you want. Indecision has often given an advantage to the other fellow because he did his thinking beforehand." Maurice Switzer

Deciding what he wants for his business is clearly one of the most important things a leader can do. Often the leader is well served having the input of key constituents on strategic matters. When a leadership team begins to stall, it is time to get clear in everyone's minds what is wanted... what is the goal.

I lead teams through excellent corporate events and retreats in Asheville, NC and other locations. I provide a proven framework to work through today's business problems and emerge with effective action plans that teams have developed and buy into. We also provide meeting facilitation training to develop key employees abilities and help transform their work groups. These trained facilitators generate process improvement profit with the team.

I have a new course on effective meetings... click here to create a new account and check it out!

Monday, March 24, 2008

Shadowboards Matter

Tolli and I visited Alcatraz during our California trip last year. The tour was excellent and provided a look at early 5S principles at work. Normally when we apply workplace organization methods we emphasize the importance of "a place for everything and everything in its place" because of efficiency. At Alcatraz, it was a matter of life and death.

Tolli and I visited Alcatraz during our California trip last year. The tour was excellent and provided a look at early 5S principles at work. Normally when we apply workplace organization methods we emphasize the importance of "a place for everything and everything in its place" because of efficiency. At Alcatraz, it was a matter of life and death.

Alcatraz inmates were considered the most dangerous of all prisoners and were held in cells most of the day. The exception was at meal time, when any prisoners who weren't in solitary confinement would eat together. There were prisoners who helped in the kitchen. The challenge for the guards was making sure this was done safely. Shadowboards enabled guards to account for every piece of cutlery.

Here you see an example of a shadowboard used in Alcatraz prison to alert guards when inmates had not returned knives.

Here you see an example of a shadowboard used in Alcatraz prison to alert guards when inmates had not returned knives. It is hard to imagine in today's prisons that tools like these might be available to inmates, but at Alcatraz, they found a way to deal with them effectively, by employing a shadowboard.

It is hard to imagine in today's prisons that tools like these might be available to inmates, but at Alcatraz, they found a way to deal with them effectively, by employing a shadowboard.While today's workplaces are much safer than the Alcatraz of the past, employing best practices, such as workplace organization -- including shadowboards -- sets apart top performing companies.

Friday, March 21, 2008

Responses to economic slowdown

Higher energy prices drive the US economy toward a slowdown. What are businesses doing in response?

In casual conversations over the past week, here is what I've heard:

Cut travel costs first, it is the easiest and most logical place to start

Cut operating costs, outside of personnel; use layoffs as last resort

Work to retain clients: avoid losing customers as a first defense

Retrench: bolster your market position by reinforcing your strengths

Innovate: develop new products and launch them now to offset sluggish sales

"Opportunity is missed by most people because it is dressed in overalls and looks like work.”

Thomas Alva Edison

What is your experience, your plan, your method to turn this opportunity into profit? Share your comments...

This may seem like a crazy time to start a business, but that's what I'm doing! Businesses need help in this economy... to generate profit from process improvement, to cut costs using virtual meetings, to harvest ideas from teams and employees, or to gain alignment with key constituents. To that end, my business offers solutions to today's toughest business challenges. My website will be up and running soon!

Thursday, March 20, 2008

Exporting... where to start in NC?

I attended a session of the Blue Ridge Entrepreneurial Council (BREC) on networking the other night, and I heard about an upcoming program that caught my attention. The North Carolina Department of Commerce is hosting several sessions on how to export to various markets. There will be trade representatives from several countries at the sessions, and local businesses can schedule free meetings with the representatives to ask questions, show their products, and find out what they need to do to begin global trading. Countries to be represented are Germany, Hong Kong, Canada, Mexico, Japan and Korea. Additionally, there will be seminars on how to do trade in various markets. The first session is on trade with China and it will be in Charlotte, March 31st. April first, a seminar on doing business in Canada will be presented in Asheville. See the program information here.

To register or for additional information on any or all of these free Lunch and Learn sessions, please contact:

Katie Newcombe: knewcombe@nccommerce.com or 919-733-7193.

Exporting is an excellent corporate retreat topic: gathering ideas on what to do, and how to do it, can be a great topic of a staff retreat to Asheville.

Developments In China

It will be 30 years since the establishment of formal communications between the US and The Peoples Republic of China this year. By all accounts, the relationship has come a long way in 30 years. It is important for businesspeople to know about developments in China, as this nation is swiftly becoming an overwhelming force in the global economy.

It will be 30 years since the establishment of formal communications between the US and The Peoples Republic of China this year. By all accounts, the relationship has come a long way in 30 years. It is important for businesspeople to know about developments in China, as this nation is swiftly becoming an overwhelming force in the global economy.Recently, Zhou Wenzhong, The Peoples Republic of China's Ambassador to the US, spoke in Ohio about developments in China. I read his speech in Vital Speeches, and provide a summary here. Zhou spoke of peace and development being the overall themes of our relationship, and that the most prominent trend is globalization driving increasing international trade and transnational direct investment. He remarked that these trends underscore the interdependence now in place between the US and China.

There will be "no glorious isolation" in tomorrow's world, based on this interdependence. There will be continued Chinese economic growth. He said that China will apply a "Scientific outlook on development," aiming to moderate growth to a manageable ongoing level. Further, China aims to continue reform and opening up, enhance social harmony, quadruple per capita GDP by 2020 (from 2000), and build a moderately prosperous society. Zhou then said China, recognizing the imbalance in trade, will try to increase imports from the US.

According to Daniel Workman, "zinc, nickel, lumber, mining & oil equipment lead China's fastest-growing exports to U.S. while tobacco, corn & precious metals are popular American imports in China.…

China Imports from U.S.

Of the $55.2 billion in American exports to China in 2006, the following product categories had the highest values.

- Semi-conductors … US$5.9 billion (10.6% of China from U.S. imports, up 74.7% from 2005)

- Civilian aircraft … $5.3 billion (9.6%, up 39.7%)

- Soybeans … $2.5 billion (4.6%, up 12.5%)

- Plastics …. $2.2 billion (3.9%, up 18.8%)

- Raw cotton … $2.1 billion (3.7%, up 47%)

- Industrial machines … $1.97 billion (3.6%, up 29%)

- Copper … $1.86 billion (3.4%, up 99.7%)

- Computer accessories … $1.82 billion (3.3%, up 27.5%)

- Aluminum … $1.7 billion (3.1%, up 90.3%)

- Steelmaking material … $1.69 billion (3.1%, up 11.9%)

Fastest-Growing Chinese Imports from U.S.

Below are American exports to China in 2006 with the highest percentage sales increases from 2005.

- Unmanufactured tobacco … US$61.4 million (up 3127% from 2005)

- Corn … $22.6 million (up 2963%)

- Oilseeds & food oils … $60.7 million (up 970%)

- Precious metals … $305 million (up 205.2%)

- Railway transportation equipment … $220 million (up 146%)"

Tuesday, March 18, 2008

Ideas Change the World

I help teams to implement a new approach to global problem solving -- by providing online meeting facilitation training.

Friday, March 14, 2008

Connections

“The person who can combine frames of reference and draw connections between ostensibly unrelated points of view is likely to be the one who makes the creative breakthrough”

Denise Shekerjian quotes

Title: Connections I

Artist: Eve Shpritser

What makes a "simply powerful meeting?" The interconnectedness of our thoughts, abilities, and memories make it possible. The skillful melding of planning and flow result in something new and different, exceptional. This is how process improvement profit is generated.

Wednesday, March 12, 2008

Patterns of Crises

The direct translation of these Chinese characters, which mean crisis, is "an opportunity riding a dangerous wind." Although crises present opportunities, most crises are unwanted and we feel better off without.

In his book, Will Your Next Business Mistake Be Fatal? Avoiding a Chain of Mistakes that Can Destroy Your Organization, Robert E. Mittelstaedt, Jr. describes a pattern traced back from crises. Mittelstaedt finds that the pattern includes these components (and I quote, from the book):

"- An initial problem, often minor in isolation, that goes uncorrected

- A subsequent problem that compounds the effect of the initial problem

- An inept corrective effect

- Disbelief at the accelerating seriousness of the situation

- Generally, an attempt to hide the truth about what is going on while an attempt is made at remediation

- Sudden recognition that the situation is out of control or “in extremis” (In extremis is a Latin phrase meaning "in the furthest reaches" or "at the point of death".)

- Finally, the ultimate disaster scenario involving significant loss of life, financial resources, or both, and ultimately, the recriminations."

If this pattern seems familiar, it should, because most business problems that become crises follow this pattern. Also, the large crises our governments face can be traced back through the same pattern.

What to do, then, to avoid these crises? Clearly, the chain of escalation must be broken. The first component of the pattern is the initial problem. So many crises start out small, in a manageable scope, yet go unfixed. An effective method of problem detecting and corrective action nips these problems in the bud.

When the initial problem gets past the first wave of defence, an interacting problem often amplifies the first one. Now a real mess is brewing. If corrective action fails here, the next phase in escalation is when those responsible begin hiding the problem or downplaying its significance. This can be done through filtering information as it goes up the chain of command. A boss can work to avoid filtering by having several lines of communication to compare messages and validate what he or she is hearing. When there is a disconnect, one of the sources is either filtering information or out of touch. Regardless, this is when help is needed but somehow doesn't show up.

Next, the crisis erupts in some undeniable way. People ask, "how could this happen?" There is enough blame to go around and lessons are learned and spread throughout the organization, but the key question is, is there a system in place to root out problems in their infancy and solve them completely? If not, be ready for more "opportunities riding dangerous winds."

With years of problem solving and corrective action experience, The Flying Toolshed implements corrective action systems so crises may be avoided all together. We believe creating opportunities for our clients rather than having opportunities thrust upon them.

bob@flyingtoolshed.com

Monday, March 10, 2008

Solving Global Warming Is Like Solving World Hunger?

In a new article, The Washington Post describes one scientist's view that to stop global warming, we need to go to zero emissions output sooner, not later. The article explains that there are no technological reasons why we can't get to zero emissions now, only political and economic reasons. There are no descriptions of how to implement zero emissions technology globally, only references to the old fossil fuel technology (burning fossil fuels has been around a while), implying that new technology is the answer. So it seems, according to the article, all we need to do is decide to fix the problem and do it. This argument is reminiscent on solving world hunger, as well. We have enough food, we have the technology. All we need is the will to fix these problems. So why don't we?

Let's analyze the global warming problem.

First, the problem: the earth's average temperature is trending upwards causing the climate to change. Figures indicate an average increase in temperature of .76 degrees C in the last 100 years. There are many who dispute this finding, others who would argue its significance. For now, let's accept it and go on to the next step, option finding.

What are options to reduce global warming? Here are some of the ideas found on the Web:

- cut or eliminate greenhouse gas emissions

- plant more trees to absorb the extra carbon dioxide

- pump sea water to the polar areas to add to the ice caps

- carbon sequestration

- issue a substance to absorb infra red radiation

- geoengineering to block or reduce solar radiation

This is a common roadblock in solving group problems. We find it in many businesses and non-profit organizations. Problems requiring cross-functional or group action must be recognized as problems first, defined, then options listed, chosen, and implemented. Lastly, the corrective action's effects must be measured and evaluated to ensure solution. Then the group can go back and find another problem.

Our Simply Powerful MeetingSM methods bring groups along this path quickly and effectively so problem definitions are established and options are developed, hurdling over the roadblocks which hold many global or cross-functional solutions at bay.

Thursday, March 6, 2008

Envisioning Progress

I am also experimenting with using small multiples, as shown below. Here I have tracked key word usage from the beginning of the workshop, "what success means," through identifying success factors, barriers to success, overcoming barriers, combining success factors, and finally, the improvement plan. You can visualize how the session evolved using this image.

Comments welcome... what would be your preference? What other ideas are there to take words into the visual realm?

Comments welcome... what would be your preference? What other ideas are there to take words into the visual realm?Tuesday, March 4, 2008

Neuroprosthetic System

From this month's Technology Review: The Power of Thought

Miguel Nicolelis continues to lead the way in neural-implant technology.

"In January a rhesus monkey named Idoya did what no other creature has done before: she made a robot walk just by thinking about it. All Idoya had to do was imagine taking a step, and the robot would actually take it."

What are the implications of neuroprosthetic systems… beyond the miracle of a paralyzed person being able to control a robot to act on his thoughts?

Monday, March 3, 2008

Problem Solving Approach Defined

Problem finding seems easy, because usually they jump up and bite us. Finding hidden problems is often an overlooked step in problem solving. Take for example a low grade "under the radar" quality problem. Often this problem gets a superficial fix and is forgotten. If after time, this problem becomes a repeated headache for a customer, it escalated to cost business. Finding the problems, therefore, is an overlooked step that can be crucial.

Problem stating is an important defining step. What is the problem and what is it not? Can you state succinctly what the problem really is? Often teams get this wrong and end up working on too broad a scope rather than zeroing in on the exact problem.

Option finding is the last part of the expansion phase, where potential solutions are generated. Here we go for quantity, developing as many creative ways to solve the problem as possible.

Now we switch gears to the convergent thinking with the decision of which options to pursue. This is done using data and experience from the process results. An action plan is developed and executed, and when completed, evaluation is made as to the effectiveness of the solution.

The next step, once that problem is solved, is to find the next problem. And the cycle goes on, and we generate process improvement profit.

We use this approach in solving problems of all kinds and we apply various tools to achieve resolution. We use lean and six-sigma approaches as well as 8-discipline approach. We provide strategic planning to work on longer term problems and develop new markets. We stick with our clients from start to finish, helping to implement solutions if desired. One of the first things we do with new clients is to sit down and discuss their process improvement problem or concern in a free initial consultation. Contact us at 828-505-1695.

*Adapted form Karl Albrecht's Brain Power.

Friday, February 29, 2008

How do you learn?

Thursday, February 28, 2008

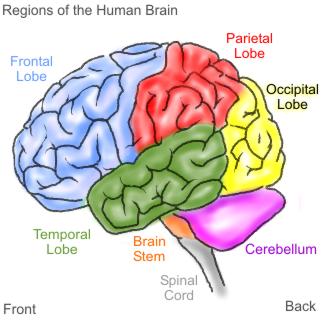

Brain Mapping Image

Here is a link to an interesting article on mapping brain connections: http://www.technologyreview.com/read_article.aspx?ch=specialsections&sc=emerging08&id=20241&a=

Here is a link to an interesting article on mapping brain connections: http://www.technologyreview.com/read_article.aspx?ch=specialsections&sc=emerging08&id=20241&a=The article in Technology Review talks about the top ten new technologies that will likely make an impact on our world over the next year. This article, about mapping neural circuits, discusses the challenges in mapping mammalian brains. Human brains have 100,000,000,000 neurons!

Wednesday, February 27, 2008

Online Facilitation Uniquely Challenging

I recently finished managing a successful global project with participants in Canada, Mexico, the US, and China. Here are a few thoughts on what worked, and what didn't:

What worked:

- I adjusted meeting times for the Chinese so they could be at work while we in North America called from home. We have the infrastructure to do this, they typically do not.

- I recorded every teleconference. I made the recordings available to every participant and generally available to interested parties within the client company. I used the recording to document meeting minutes, including follow up actions. When memory lapses occurred, and they always do, this became valuable.

- I posted all documents, schedules, project requirements, photographs, and meeting minutes on a shared folder where everyone could review them at their leisure.

- We met on a regular schedule, every two weeks. This allowed for progress between meetings. Weekly meetings sometimes are overly burdensome.

What didn't work (watch out)

- Language barriers existed so it was imperative to follow up every conference call with a written confirmation and to specifically ask for acknowledgement. Key points are dates and specifications. Without concrete agreement, there was ambiguity, and error. Thread specifications seem to be the commonly missed item in China. The take away: demand positive confirmation on every date and every requirement.

- Even with seemingly overdone written and verbal communication, preconceived notions caused fumbles and stumbles. An example: sample making. If samples are required, get more than the minimum you think you need... try doubling that figure. We made more than we thought we would need and we actually ran out... so err on the side of caution.

Wasted Time

Ideas are like the wind, mostly they just blow by. With our process, it's like putting up a huge wind turbine capturing your team's ideas and turning them into power -- idea power -- power for executive action.

What's your story... the worst meeting you've ever been in? Where was it? What was the purpose? What happened? Why did this meeting happen at all? I will feature the most interesting story in an upcoming post. Thanks!

I have a new course on effective meetings... click here to create a new account and check it out!

Tuesday, February 26, 2008

Imperiled Start Up

Ralph Waldo Emerson

I was in charge of a new plant start up -- a risky assignment since many launches went badly, and this was my first try at it. My responsibility was to take an empty shell of a building and populate it with machines and people, processes and systems, and generate profit.

This launch depended on implementing some unproven new technology, a red flag. The technology in question was elaborate mechanical tooling which deployed in a CNC machine to cut a precise spherical radius on the ID of a casting. To perform this feat, the CNC equipment loaded the casting, then the tool, in the shape of a cylinder with a slot cut out of the side, was inserted into the casting opening. The tool had an ingenious mechanical device to deploy the cutter from the slot using a spine-like grooved lever. The cutting was done at high speed (turning the tool), and at the end of the cycle, the tool was quickly stopped then the cutter was retracted using spring action, hiding the cutter away in the cylinder again, and the tool was pulled from the casting. Nice Idea!

We got the equipment in and set up. We hired great people. We did a lot of training. All the while, I kept hearing about broken cutters. This was troubling because it was unproven technology and the entire start up depended on success. Not only that, cutters cost over $100 each, so the budget was feeling the pain.

We talked to the experts at the toolmaker. They tried to fix the problem. They kept trying, but to no avail. Finally, after weeks and weeks of trying, it became clear that this start up was in peril.

I ordered autopsies of each broken cutter. We opened up some tools to see what was happening. The engineers were puzzled and befuddled. We were asked to start working on "Plan B," which would cost a lot in capital to retrofit our operation. Then I saw the key.

Each tool that had a broken cutter, when opened up, had several small retracting springs which had toppled in the deceleration. The centrifugal force caused the springs to fall over on their side, laying down and providing no force to retract the cutter.

A big shock-absorber spring, that's what we needed! Once we figured out how to place strong enough spring coaxial with the center line, the decelerating forces were overcome by better engineering. The funny thing was, it took a tremendous effort to convince the inventor of the technology to change it... even though the initial design was failing.

My take-away: be open to new ways of looking at things, especially if we invented something and the old way isn't working. When we invent something we are proud of, great! When improvements to that invention come along, better! Often new ideas come from the most unlikely sources, so have eyes and ears open, and minds prepared to accept the possibility of something better.

Please let me know about a time you saw an inventor learn how to improve their invention from an unlikely source...

For more information on the "imperiled start up": http://www.mmsonline.com/articles/069903.html

The Advantages of Closing a Few Doors

By JOHN TIERNEY

Published: February 26, 2008

We can always tell ourselves that it’s good to keep options open, but is it really?

http://www.nytimes.com/2008/02/26/science/26tier.html?ex=1361768400&en=0ced27ff172610bf&ei=5124&partner=permalink&exprod=permalink

Monday, February 25, 2008

Asheville Tree

Meeting Facilitation Training

"Felt more camaraderie, progression. Really moving forward."

"Improved clarity, focus."

"Really enjoyed this today."

"Great that we're on a path moving forward."

"Really going to help us implement things that we talked about but never did."

"This was so productive. We got everyone’s input."

"I'm so grateful to now to move forward and appreciate all your time, effort, and caring."

"Bob and Tolli do an awesome job helping us focus on our problem areas and realizing what we need to do in order for our group to become successful."

"Great process, promotes cooperative visualization and goal setting."

"You guys kept things moving and kept us focused and engaged -- so we could come up with a plan of action that we all agreed on!! Wow!! ... Impressive!"

"Excellent at keeping the group focused. Clear and workable visuals. Accomplished goals and made it fun."

"Loved seeing many ideas trickling down."

"Excellent workshop!"

I have a new online course on effective meetings... click here to create a new account and check it out!

Sunday, February 24, 2008

Improving your Vocal Power

Do you ever listen to yourself on a tape recorder or your voice mail “away message” and go UGH!? We usually don’t like our own voices, do we? But voices are an important asset for each of us. Would you take anyone seriously if they sounded like Bugs Bunny? No

We can’t all sound like a radio announcer, but I am going to tell you how to make the most of the voice you have.

Your voice is important, it conveys your message in multiple ways: as a mode of communicating facts, but also to represent your emotions and credibility. In this presidential campaign year, it is instructive to see just how important voice, and delivery are. It may make the difference in deciding who our next President is. Not only is voice important to these presidential candidates, it also is important to you. You use your voice all the time, on the phone, in job interviews, giving presentations, interacting at work. Having a more powerful voice can mean a lot to you, personally, socially, and financially.

I study leadership and I kept running into many references to the power of voice in leadership. Think of a great leader whom you admire. What does that leader sound like? Powerful, I bet. I’m thinking of Martin Luther King, Jr. and his “I have a dream” speech. Maybe you’re thinking an FDR fireside chat, or President Kennedy’s voice painting the path to the moon. But how do you work toward sounding like these great leaders?

There are three main parts to improving your voice.

First, it’s getting the best sound, which includes the right pitch, tone, and inflection. Vocal pitch is simply the frequency of the sound you make with your voice, similar to the wavelength. We’ve all heard the term high pitch – you know what I mean then. The way to find your best pitch is to hum, adjusting the pitch, until you feel a vibration around your eyes. Go ahead, start humming, and notice the area around the nasal cavity behind your eyes for a vibration. When it sort of tickles, you’ve found your optimal pitch, whether it’s hi or low, that’s where you want your speaking voice to be. (As a side note, Abraham Lincoln was a high-pitched speaker -- so go with what you have, not what you think you should sound like.) Also remember when it comes to optimizing the sound of your voice, use inflection, and add feeling to your words. You can create a warm, friendly and comfortable sounding voice, if you feel that way, and to feel that way, create warm comfortable images for yourself. To change your tone of voice, picture or feel the emotion you wish to convey, and it will come out expressed in your voce.

Next, it is important to vary the pattern in your speech. You can do this by changing the speed from fast to slow, changing rhythm, and adjusting the placement of your voice. Practice doing that: go back to your pitch you found before, where you felt it in your face... now work on imagining your chest as the source, touch your diaphragm, below your sternum, and see if you can feel the sound there. Next, imagine that the sound is radiating from your diaphragm, up to your face, then imagine that sound emitting from the top of your head. This is how you can really project your voice and create an authoritative voice.

The last step is doing what you are likely to least enjoy: listening to your own voice. Pick one day a week, say Monday, and make a point of recording yourself and evaluating your own voice. Is it pitched well? Are you varying tone and inflection so you don’t sound monotonous? Are you able to adjust tempo and rhythm to make your voice interesting, and are you placing your voice optimally? I promise, if you take the time to practice, you will be pleased at the improvements.

Now you have learned something important about yourself: what your vocal pitch is, how to avoid a monotone, and how to project your voice to emit power and emotion. Now you have notes: I’ve included notes from of this blog, and a vocal warm-up you can use to increase the power of your voice – and you can use the warm-up before that next big speech you give. Remember, while you can apply this tonight, only by practicing will you fully develop your voice to maximize your vocal power.

Vocal Warm-up instructions: find your pitch, with rhythm and inflection, say the following phrases while projecting your voice from your diaphragm though your facial mask.

Eat each green pea. Aim straight at the game. Ed said get ready.

It is in Italy. I tried my kite. Oaks grow slowly.

Father was calm as he threw the bomb on the dock.

An awed audience applauded Claude.

Go slow Joe, you're stepping on my toe.

Sauce makes the goose more succulent.

Up the bluff, Bud runs with the cup of love.

Red led men to the heifer that fell in the dell.

Maimed animals may become mean.

It's time to buy a nice limeade for a dime.

Oil soils doilies.

Flip a coin, Roy, you have a choice of oysters or poi.

Sheep shears should be sharp.

At her leisure, she used rouge to camouflage her features.

There's your cue, the curfew is due.

It was the student's duty to deliver the Tuesday newspaper.

He feels keen as he schemes and dreams.

Much of the flood comes under the hutch.

Boots and shoes lose newness soon.

Ruth was rude to the youthful recruit.

Vivid, livid, vivifying. Vivid experiences were lived vicariously.

Oddly, the ominous octopus remained calm.

The pod will rot if left on the rock.

Look, you could put your foot on the hood and push.

Nat nailed the new sign on the door of the diner.

Dale's dad died in the stampede for gold.

Thoughtful thinkers think things through.

Engineer Ethelbert wrecked the express at the end of Elm Street.

Notes:

Why is the sound of my voice important?

Your voice conveys your message in multiple ways, in the facts and in feelings perceived by your audience as heard in your voice.

What is vocal pitch?

Pitch is the frequency of sound waves your voice makes. You can vary the frequency, or pitch, from high to low, but there is an optimal pitch for your voice.

How do I find my natural, or optimal, pitch?

Find your natural pitch by humming, changing the sound up and down until you feel your facial mask, the area around your sinuses and behind your eyes, vibrating. This is the most natural pitch for your voice and where you should target your speaking voice.

How do I keep my voice interesting to listen to?

By varying patterns in your voice, you will keep your voice interesting to listen to. Natural ways to vary vocal patterns are to change tone and inflection. You can also adjust patterns in your voice, like the tempo, rhythm, and placement of your voice.

How can I control my tone of voice?

One way to change your tone of voice is to imagine the emotion you wish to express, either in an image, a sound or voice you’ve heard, or an action that represents the emotion. By embodying that feeling, your voice will express it in the tone you desire. Some tones of voice you may wish to express include courageous, authoritative, passionate, respectful, compassionate, or joyful.

What do I need to do to improve my voice, to get the most out of it?

You can improve the power of your voice by practicing at least weekly, listening to your voice, and working on improving the pitch, tone, inflection, tempo, rhythm, and placement of your voice.