Here is advice from Wired Magazine on how to improve your brainpower.

Takeaways:

- Have a learning plan. Think about what you need to know and focus your efforts on the highest value information that is easiest to learn.

- Have a learning plan. Think about what you need to know and focus your efforts on the highest value information that is easiest to learn.

- When memorizing facts, mix them up and set timers to randomly distract you during your memorizing.

- Regular aerobic exercise is vital... even walking works, and practice good breathing.

- Limit caffeine but keep a pretty steady stream of it in small amounts throughout the day

- Figure out and use your learning style, whether it be visual, kinesthetic, listening, or tactile.

- Regular aerobic exercise is vital... even walking works, and practice good breathing.

- Limit caffeine but keep a pretty steady stream of it in small amounts throughout the day

- Figure out and use your learning style, whether it be visual, kinesthetic, listening, or tactile.

Other comments follow the article links below:

Get Smarter: 12 Hacks That Will Amp Up Your Brainpower

1: Distract Yourself -- this is possibly a good approach for memorizing but seems hard to do.

2: Caffeinate With Care -- good advice; one cup of coffee a day followed by small, regular doses

3: Choose Impressive Information -- interesting idea... memorize useful and easy facts

4: Think Positive -- great advice for learners: a virtuous cycle!

5: Do the Right Drugs -- huh?

6: Juice Your IQ Score -- good advice that ties with 3 and 4

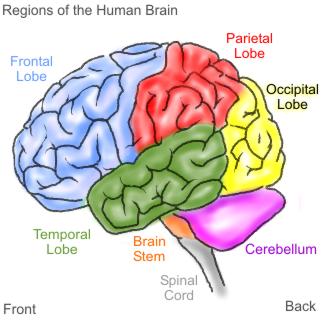

7: Know Your Brain -- exactly how does this help?

8: Don't Panic -- right on... how do we not panic? If you do, know your IQ plummets.

9: Embrace Chaos -- mix up things to make them somehow easier to remember.. counter intuitive.

10: Get Visual -- for visual learners, a big YES

11: Exercise Wisely -- breathing and aerobics... the brain uses a disproportionate amount (20%) of the oxygen in your blood, so improving your cardio-vascular system will help your brain.

12: Slow Down -- good advice for improving reading comprehension, but practice at reading quickly does work, so aim for the optimal: 500 wpm according to the article.

1: Distract Yourself -- this is possibly a good approach for memorizing but seems hard to do.

2: Caffeinate With Care -- good advice; one cup of coffee a day followed by small, regular doses

3: Choose Impressive Information -- interesting idea... memorize useful and easy facts

4: Think Positive -- great advice for learners: a virtuous cycle!

5: Do the Right Drugs -- huh?

6: Juice Your IQ Score -- good advice that ties with 3 and 4

7: Know Your Brain -- exactly how does this help?

8: Don't Panic -- right on... how do we not panic? If you do, know your IQ plummets.

9: Embrace Chaos -- mix up things to make them somehow easier to remember.. counter intuitive.

10: Get Visual -- for visual learners, a big YES

11: Exercise Wisely -- breathing and aerobics... the brain uses a disproportionate amount (20%) of the oxygen in your blood, so improving your cardio-vascular system will help your brain.

12: Slow Down -- good advice for improving reading comprehension, but practice at reading quickly does work, so aim for the optimal: 500 wpm according to the article.